Process and technological continuous improvement is planned on a regular basis to satisfy international standards and client needs.

A Casting model is made with machining allowance and contraction allowance depending on the requirement of specific copper based alloy.

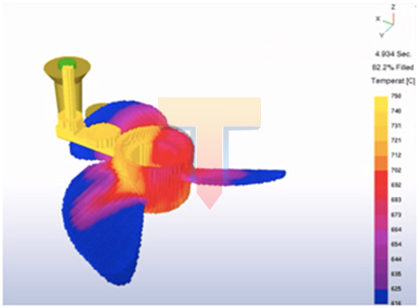

The required components are run with the simulation software to predict the internal soundness, feasibility and best method to cast the component.

The simulation helps to identify the defects and to eliminate by running multiple iterations by using the right gating & risering system. The right gating system is followed to have desired flow and the optimum risering to meet the feed volume requirements.

We have in house 3D plating facility which we used 3d prototyping and pattern making for faster and effective process of pattern making. with superior finish. the size of prototype and pattern wich can we make is 6inc x 6inc x 6inc

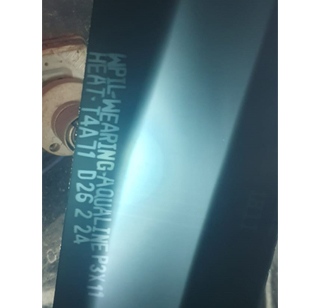

The patterns are manufactured either in wood (or) Aluminium based on usage and the surface finish requirements. The patterns are provided with required contraction allowance and machining allowance as per the grade demands.

Tarasree has a dedicated storage area having more than 4000 patterns.

The process employed is CO2 Sand Moulding & Greens and Sand Moulding which generates the lowest amount of gases due to mould-metal reaction along with better mould hardness and less moisture content. The moulds are painted well to prevent metal penetration and later baked properly.

The exothermic / insulating sleeve and filters are used for effective, clean and sound casting.

Tarasree has different sizes of induction furnaces to handle different alloys and weight requirements.

Digital pyrometers are used for accurate temperature measurement.

Deoxidation and degassing procedures are followed for achieving clean metal.

| Induction Furnace : | Inductotherm |

| Max. charge capacity : | 1600 kgs |

Ladles of 100 kg, 250 kg, 500 kg, 1000 kg & 2000 kg are used depending on the metal volume requirements. Ladles are insulated with high refractory materials to withstand high temperature and to overcome heat losses. The pouring design parameters are ensured with safety while filling the molds.

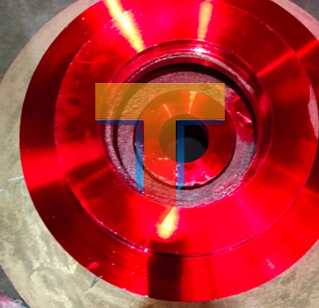

The castings with sprue, runner, ingate and risers are removed and further shot blasted and ground to meet the drawing finish requirements.

For all Copper-base alloys like Nickel Aluminium Bronze, Manganese Bronze castings, Dye-penetrant Examination and Radiography testing are performed.

MPI are not applicable for these grades.

The operators are qualified to ASNT level 2.

Tarasree can cast Radiography Level 1 castings.

The chemical and Mechanical properties are analysed for every melt cycle to ensure that the customer & standard requirements are met.

Spectrometer (32 elements ARL)

Hardness testing machine

Sand Testing Laboratory (Permeability, Core gas, Sand moisture teller, Mold Hardness, Mold moisture tester)

The machine shop is equipped with Turning machines like lathes and CNC to perform proof machining of valve bodies, bonnets and internals.